Powder Coating Technologies

Innovation Drive Success

CED Coating Technologies

01

Word-Class Technology

02

Quality Standard

03

Productive Capacity

About Us

Our Capabilities

What We Do

Our Services

Ambition Auto Engineering specialize in precision-driven processes including following services

Laser Cutting

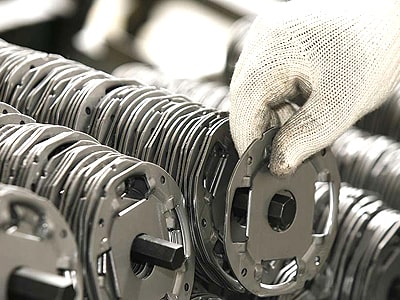

CED Coating

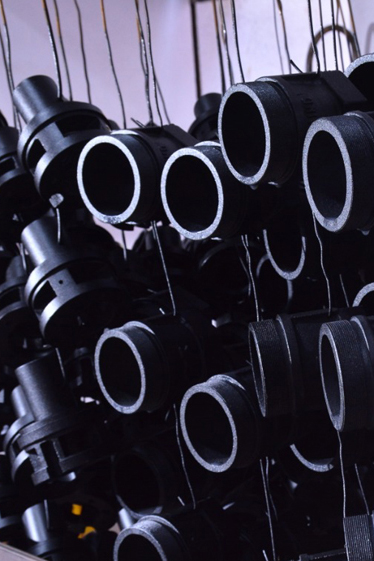

Powder Coating

Stamping

Bending

Welding

Precision Coating Solutions:

Enhancing Durability with Advanced

CED & Powder Coating Technologies

Frequently Ask Questions

Question & Answers

CED (Cathodic Electro Deposition) coating is a type of electrocoating process where a metal part is submerged in a bath of electrically charged paint particles. The coating provides uniform protection, especially in hard-to-reach areas, and is widely used for corrosion resistance in automotive and industrial applications.

The electric current attracts the solids, coating all surfaces and joints. Once the coating reaches desired thickness it insulates the components, reducing the coating application until there is a uniform layer of protection. Resin in the paint solids assist adhesion while providing corrosion protection, durability and toughness.

CED coating offers excellent corrosion resistance, providing a long-lasting protective layer that extends the lifespan of metal parts. Its uniform coverage reaches hard-to-access areas, ensuring complete protection. Environmentally friendly and highly durable, CED coating is ideal for automotive, industrial, and appliance applications.

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a metal surface. The coated part is then heated, causing the powder to melt and form a durable, smooth, and protective layer. Known for its excellent resistance to chipping, scratching, and fading, powder coating is widely used for industrial, automotive, and household items.

Powder coating provides a durable, long-lasting finish with excellent resistance to chipping, scratching, and fading, making it ideal for outdoor and industrial applications. This eco-friendly process produces minimal waste and eliminates the need for harsh solvents, while offering a wide range of color and texture options. It enhances both appearance and protection for metal surfaces.

Laser cutting offers precision and versatility, allowing intricate designs and complex shapes to be cut with high accuracy. This non-contact process reduces material waste and minimizes the risk of damage, resulting in smooth edges and a clean finish. Ideal for various materials, laser cutting is widely used in industries like automotive, electronics, and manufacturing.

Contact Us Now

Free to

Contact Us

About Company

Numeric Status

We Proud To Serve

Our clients are our trusted partners, and we are dedicated to delivering excellence to meet their unique needs.

Testimonials

What Our Clients Say

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Mahesh Patil

CEO John Deere

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Monika Shah

Director JCB

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit.